Modular product design has moved well beyond niche or experimental use cases. Today, it’s a practical strategy for teams looking to extend product lifecycles, reduce waste, and give users more control over how products evolve over time. As markets demand faster innovation cycles and customers expect products that adapt to their needs, modularity offers a compelling path forward.

For product leaders and design teams, the shift toward modular systems isn’t just about sustainability—it’s about building resilience into products and businesses alike. When executed thoughtfully, modular design can unlock flexibility, improve serviceability, and create stronger long-term value.

What Is Modular Product Design?

At its core, modular product design is the practice of creating products from interchangeable, self-contained components that can be independently developed, replaced, upgraded, or repaired. Each module performs a specific function while integrating seamlessly into the overall system.

Unlike fully integrated designs—where components are tightly coupled and difficult to separate—modular products are intentionally structured to evolve. This approach can apply across physical products, digital-physical ecosystems, and even service models.

Common examples include:

- Consumer electronics with replaceable batteries or camera modules

- Furniture systems that scale or reconfigure over time

- Medical devices designed for component-level servicing

- Commercial equipment with swappable wear parts

The real value of modularity lies not in the components themselves, but in how the system is designed to accommodate change.

Flexibility as a Competitive Advantage

Markets shift quickly. Technologies advance. User needs evolve. Modular product architectures give companies the flexibility to respond without starting from scratch.

From a business perspective, modularity can:

- Enable faster iteration and parallel development

- Support multiple product variants from a shared platform

- Reduce development risk by isolating changes to specific modules

- Extend product relevance as new features or technologies emerge

For startups and growth-stage companies, this flexibility can be critical. Instead of committing to a single, rigid product configuration, teams can design a core platform and expand strategically based on customer feedback or market demand.

From an enterprise standpoint, modular systems help manage complexity across large product portfolios while maintaining consistency and brand coherence.

Modularity as a Driver of Business Performance

Beyond design flexibility, modular product systems can have a direct and measurable impact on business performance. For many organizations, modularity becomes a strategic lever for revenue growth, cost control, and portfolio efficiency.

A well-structured modular platform can support Good–Better–Best SKU strategies, allowing companies to serve multiple market segments without developing entirely new products. By varying feature sets, materials, or performance modules, teams can expand offerings while maintaining a shared core architecture.

Modular systems also enable faster line extensions and product refreshes. Instead of redesigning an entire product to respond to new customer needs or emerging technologies, teams can update or introduce specific modules—shortening development timelines and reducing engineering risk.

From a portfolio perspective, modularity allows companies to diversify intelligently. Shared platforms reduce tooling, validation, and manufacturing overhead while improving speed to market. For leadership teams focused on ROI, modular design isn’t just a design philosophy—it’s a way to scale product lines more efficiently and make future investment decisions with greater confidence.

Designing for Repairability and Longevity

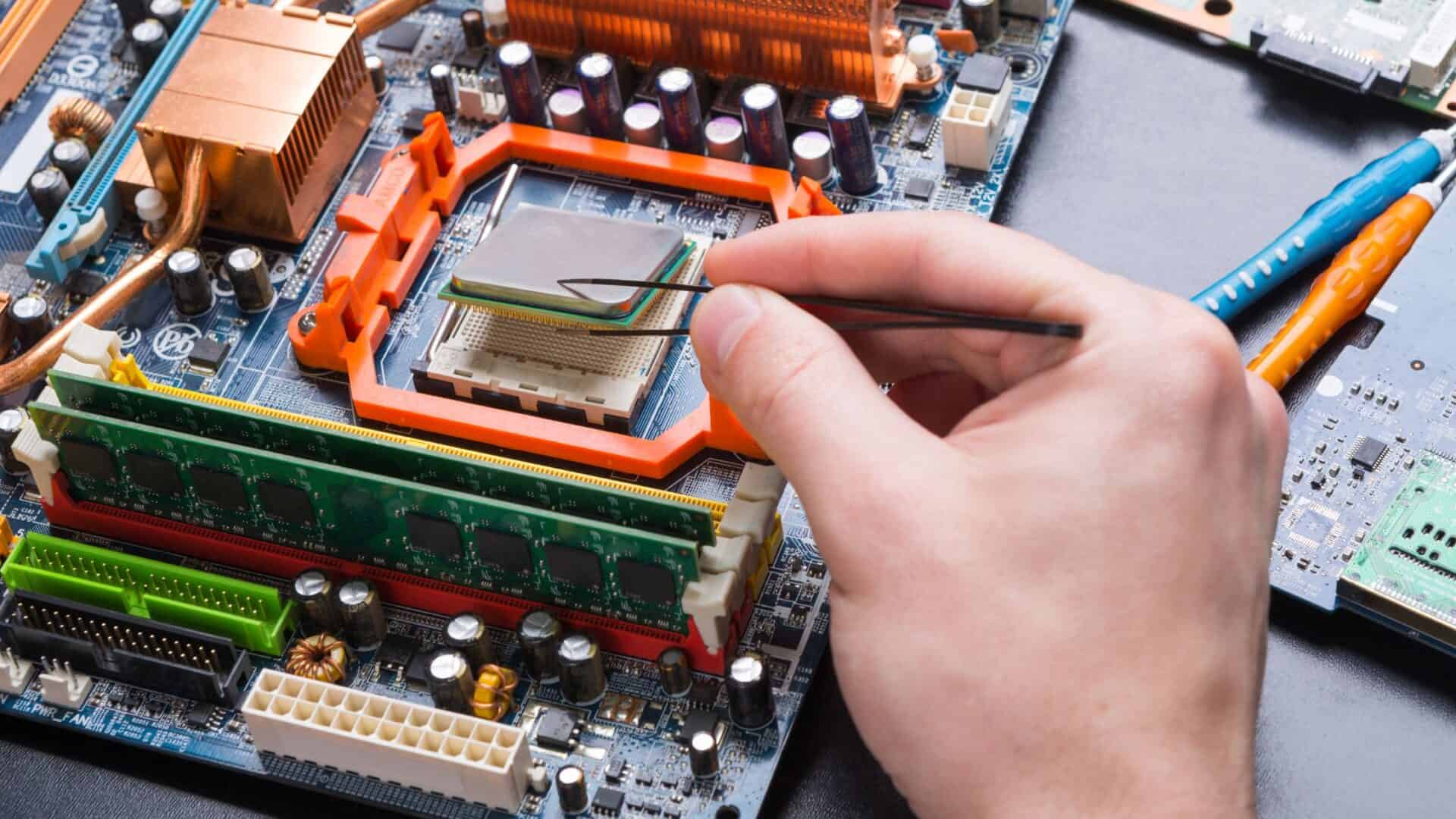

Repairability has become a central concern for both consumers and regulators. Modular design directly addresses this by making products easier to maintain, service, and refurbish.

Designing for repairability means:

- Components can be accessed without specialized tools

- High-wear parts can be replaced independently

- Failures don’t require full product replacement

- Service teams can diagnose and resolve issues more efficiently

This approach not only reduces environmental impact, but also lowers total cost of ownership for users—an increasingly important differentiator in both consumer and commercial markets.

For medical and industrial products, repairable modular systems can also minimize downtime and improve operational reliability, directly affecting business outcomes for end users.

User Empowerment Through Modularity

One of the most overlooked benefits of modular design is how it shifts the relationship between users and products. Instead of passive consumption, modular systems invite participation, customization, and agency.

User empowerment can take many forms:

- Allowing users to upgrade features as needs change

- Enabling personalization without compromising core performance

- Supporting accessibility through adaptable components

- Giving users confidence that their product won’t become obsolete overnight

When users feel invested in a product—because they can understand it, maintain it, or evolve it—they’re more likely to trust the brand behind it. This emotional and functional connection often translates into stronger loyalty and longer product lifespans.

A practical example of this approach can be seen in the Weber Slate modular cooking concept, where CHOI Design Group was brought in to help pioneer the Weber Works system and help Weber’s design team explore how modular thinking could empower users while supporting a scalable product platform.

By applying modular principles at the system level, CHOI Design Group enabled configurable components and accessories that allow users to tailor the cooking experience to their habits and space—without fragmenting the overall ecosystem. While not every element is modular in a traditional mechanical sense, the project demonstrates how modular thinking can drive user choice, platform longevity, and future line extensions while reinforcing brand cohesion.

Sustainability Beyond Materials

Sustainability in product design is often framed around materials and manufacturing processes. While those factors matter, modularity addresses sustainability at a systems level.

Modular products support circular design principles by:

- Reducing waste through component reuse and replacement

- Enabling refurbishment and secondary markets

- Simplifying disassembly for recycling

- Extending product lifecycles without full redesigns

For companies navigating ESG commitments or sustainability reporting, modular design offers measurable, long-term impact—not just surface-level improvements.

Importantly, sustainability-driven modularity must be intentional. Poorly executed modular systems can increase complexity, cost, or failure points. Strategic planning and rigorous engineering are essential to ensure that modularity delivers real value.

Designing Modular Systems That Actually Work

While modular design offers clear benefits, it also introduces challenges. Successful modular products balance flexibility with coherence, and adaptability with usability.

Key considerations include:

- System architecture: Defining clear interfaces between modules

- User experience: Ensuring modularity doesn’t complicate use or assembly

- Manufacturing strategy: Aligning modular components with scalable production

- Brand consistency: Maintaining a cohesive visual and tactile language

- Future-proofing: Anticipating how modules may evolve over time

This is where experienced product design partners add significant value. Modular systems require cross-functional alignment—from industrial design and engineering to supply chain and go-to-market strategy.

Modularity as a Strategic Design Decision

Modular product design isn’t a universal solution, nor should it be applied by default. But when aligned with business goals, user needs, and long-term product strategy, it can be a powerful differentiator.

For product teams, the key question isn’t “Should we design modularly?” but rather “Where does modularity create meaningful value?” Answering that requires a deep understanding of users, markets, and technical constraints—along with a willingness to think beyond single product launches.

CHOI Design Group approaches modularity as a strategic design decision, not a stylistic trend. By integrating research, systems thinking, and real-world execution, they help teams design products that are adaptable, durable, and built for long-term success.

Looking to design products that last longer, adapt faster, and deliver more value over time?

CHOI Design Group partners with product teams to turn strategic ideas into market-ready solutions. Contact CHOI Design Group to start the conversation.